New method to manufacture high density data storage

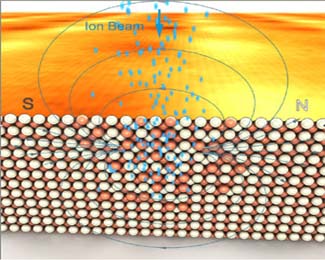

These methods of creating organised networks of nanometric-sized ferro-magnetic structures is based on the local generation of magnetism (i.e. magnetic structures embedded in a non-magnetic matrix) using ion irradiation processes which can be focalised or by working through lithographically designed masks.

In computer hard disks, information is stored in the form of changes in the orientation of small magnetic dots measuring less than 100 nanometres in diameter and distributed uniformly on top of a non-magnetic substrate surface. As the dimensions of these dots become smaller and their stability increases the greater the storage capacity of disks. Each information unit, or bit, currently requires placing from 100 to 600 dots in the same orientation in order to guarantee their stability and prevent any loss of information. This limits the capacity of hard disks since every time a bit is significantly reduced in size (in order to increase information density), the dots it contains become so small that they are no longer magnetic and thus cannot store data.

A group of researchers from the Department of Physics at Universitat Autònoma de Barcelona, the research centre Forschungszentrum Dresden-Rossendorf, Germany, the CIN2 (ICN-CSIC), and further research institutions were able to develop a process which differs from the conventional manufacturing of materials for magnetic data storage and permits reducing the diameter of the magnetic structure to less than 100 nanometres. With this new method, it is possible to use a non-magnetic surface to generate small ferro-magnetic areas, or nanomagnets, almost without altering the topography of the lithographic material. This technique can be done with focused ion irradiations or by irradiation through lithographed masks which allow selective interaction with the material in order to generate networks of magnetic areas where ions interact with the material. These are embedded in a non-magnetic matrix, an area of the material which does not interact with the ions. It is important to note that the fact that the magnetic bits do not have a corrugated surface but are smooth as the rest of the material and that this material is not magnetic are the two basic requirements in order for it to serve as a magnetic data storage. The almost imperceptible modifications to the surface of the irradiated areas permits the read/write heads to fly extremely close to the surface without producing any tribological problems, while the non-magnetic feature of the material structure provides the magnetic bits with the needed stability. Future related research studies could produce magnetic data storage devices with a higher density than that available today, as well as the possibility to magnetise other materials lithographically.

The research was published in the nanotechnology research journal Small. Participating in the research were Enric Menéndez, Maria Dolors Baró and Santiago Suriñach from the UAB Department of Physics; Maciej Oskar Liedke and Jürgen Fassbender from the research centre Forschungszentrum Dresden - Rossendorf in Germany; Thomas Gemming from IFW Dresden,Germany; Anja Weber and Laura J. Heyderman from Paul Scherrer Institut in Villigen, Switzerland; K. V. Rao from the Royal Institute of Technology, Sweden; Seetharama C. Deevi from the Philip Morris Research Center in Richmond, USA; Jordi Sort from ICREA (Institució Catalana de Recerca i Estudis Avançats) at the UAB Department of Physics; and Josep Nogués from ICREA and head of the Magnetic Nanostructures Group at CIN2 (ICN-CSIC), a centre formed by the Catalan Institute of Nanotechnology co-owned by Josep Nogués and the Higher Council for Scientific Research (CSIC).

References

Direct Magnetic Patterning due to the Generation of Ferromagnetism by Selective Ion Irradiation of Paramagnetic FeAl Alloys. Enric Menendez, Maciej Oskar Liedke, Jürgen Fassbender, Thomas Gemming, Anja Weber, Laura J. Heyderman, K. V. Rao, Seetharama C. Deevi, Santiago Surinyach, Maria Dolors Baro, Jordi Sort, Josep Nogues. Small 2009, 5, No. 2, 229-234