Fruit-like odor from organic waste

Using aromas to improve the organoleptic characteristics of final products in industries such as food, cosmetics and pharmaceuticals is a growing practice whose development is constant since these additives affect the final consumer perception. Aromas are constituted of a great variety of volatile and non-volatile compounds like some alcohols, aldehydes or esters, as well as more complex species like aromatic, phenolic or sulfur-based compounds, that give to our brain the perception of odor.

Aromas are found in nature in many matrices such as food, spices, plants, flowers or wines. However, their extraction from these sources is limited by their low concentration, rendering the process inefficient and costly. Having this in mind, the aroma production has turned into chemical synthesis processes which generate products of much lower cost, but at the same time, with a lower quality. This, considering a synthetic aroma only partially reproduces the characteristics of their natural counterpart. As an alternative, some biochemical pathways based on the action of microorganisms (bacteria, fungi, yeasts, etc.) and their enzymes have been developed to synthesize these compounds. In this case, aroma compounds are obtained as secondary metabolites, derived from processes associated with the growth of the microorganisms.

Even most of the biotechnological processes are performed by submerged fermentation, in the research group GICOM from UAB, we coupled the solid-state fermentation process (SSF) with the use of renewable sources and organic wastes as a raw material of the processes. In this way, the resulting processes can be considered more sustainable, environmentally friendly and cheaper.

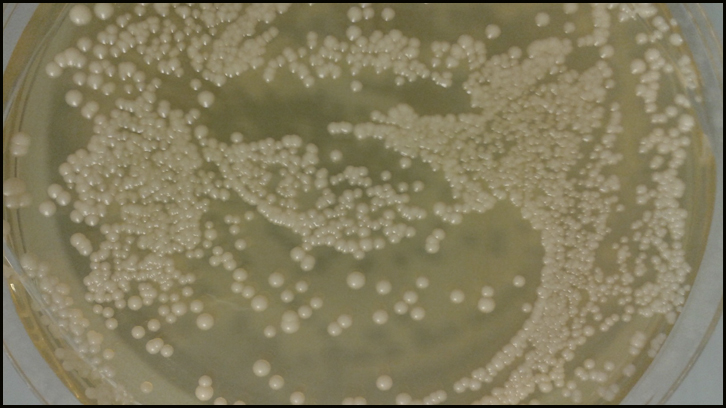

This study has focused on the productive process for obtaining fruit-like aromas through the SSF of sugarcane bagasse and sugar beet molasses derived from the sugar industry. Besides, the microorganism Kluyveromyces marxianus has been used for this purpose. This strain is a versatile yeast capable of transforming available sugars from the residues, into a mixture of esters, alcohols and aldehydes with fruit-like odor.

From this research, it was possible to define the cause-effect relationships between the operating conditions of the process and the final amount of fruit-like compounds. In addition, it has been established how these conditions affect the proportion of alcoholic and esters compounds, thus, defining the aroma profile to be obtained through the process.

Given these conditions, the use of this technology appears as a viable alternative to the production of aroma compounds, following the principle of transformation "from waste to product".

Results obtained have been published in Journal of Cleaner Production (vol 158, 8-17) by Oscar Martínez, Antoni Sánchez, Xavier Font, Raquel Barrena, Valorization of sugarcane bagasse and sugar beet molasses using Kluyveromyces marxianus for producing value-added aroma compounds via solid-state fermentation.

Departament of Chemical, Biological and Environmental Engineering

Universitat Autònoma de Barcelona

References

Martínez, O., Sánchez, A., Font, X., Barrena, R. Valorization of sugarcane bagasse and sugar beet molasses using Kluyveromyces marxianus for producing value-added aroma compounds via solid-state fermentation. Journal of Cleaner Production 158 (1) 8-17 (2017).