Physics

Novel magnesium alloy for biomedical applications

Scientists from the Physics and the Cellular Biology Departments at the Universitat Autònoma de Barcelona (UAB) and from the Catalan Institution for Research and Advanced Studies (ICREA) have developed a novel noncytotoxic magnesium alloy with improved mechanical performance and delayed corrosion phenomena through small palladium alloying. This novel alloy has potential applications as biodegradable implants.

References

S. González, E. Pellicer, J. Fornell, A. Blanquer, L. Barrios, E. Ibañez, P. Solsona, S. Suriñach, M. D. Baró, C. Nogués, J. Sort. “Improved mechanical perfomance and delayed corrosion phenomena in biodegradable Mg-Zn-Ca alloys through Pd-alloying”. J. Mech. Behav. Biomed. Mater. 6 (2012) 53-62.

At the present time various metallic materials such as steels, titanium alloys, etc are used for biomedical applications. For example they can be used as implants since they are suitable for bearing large loads without excessive deformation and permanent dimensional changes. In spite of their extended use, the stiffness of these materials is much higher than that of human bone, which can cause bone resorption, cell death and implant loosening. The problem of bone resorption (mass loss) is similar to that faced by astronauts in space. This loss occurs because the absence of gravity disrupts the process of bone maintenance in its major function of supporting body weight.

This limitation can be overcome using magnesium alloys since they exhibit very low stiffness. Moreover, magnesium alloys have good biocompatibility and are biodegradable (non-toxic materials that become reabsorbed by the human body after a certain period of time), which is a major advantage because it avoids the need of removing the implant from the body once the patient has recovered. However, the problem with some magnesium alloys is their exceedingly high corrosion rates in physiological conditions, which makes their biodegradability to be faster than the time required to heal the bone. For this reason it is important to decrease the degradation rate of magnesium alloys.

In our work we have shown that a proper and effective way to delay the beginning of corrosion phenomena is alloying with palladium as evidenced from the shift in the corrosion potential towards more positive values. Also the surface of the corroded sample is smoother and contains lower amounts of holes in the palladium-containing alloy. This element has been used for many years as major component in dental casting alloys due to its high corrosion resistance and low toxic activity. Thus, controlling the concentration of palladium in the alloy, we can control the degradation rate of the implants, causing them to be degraded when the bone is recovered.

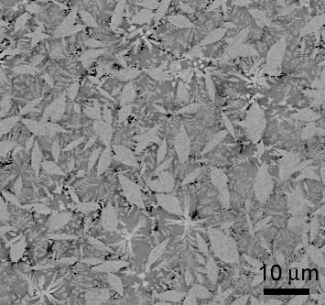

The microstructure of the initial magnesium alloy, which consists of an amorphous matrix with finely dispersed crystallites, drastically changes with small palladium content, which is sufficient to obtain a fully crystalline microstructure (Figure). From nanoindentation tests we have observed that the addition of this element increases the hardness of the alloy, mainly due to the formation of mechanically hard crystalline phases, and increases the wear resistance. The improvement of the wear resistance is potentially interesting to avoid wear debris that results in inflammatory reactions.

Cytotoxicity tests do not show significant increase of dead cells after culturing for 27 hours, which confirms that this novel alloy is not toxic and thus can be used as potential biodegradable implants.

Sergio González, Eva Pellicer

Department of Physics

2026 Universitat Autònoma de Barcelona

B.11870-2012 ISSN: 2014-6388