Reusing bottles could reduce Catalonia's wine-making sector's carbon footprint by up to 28%

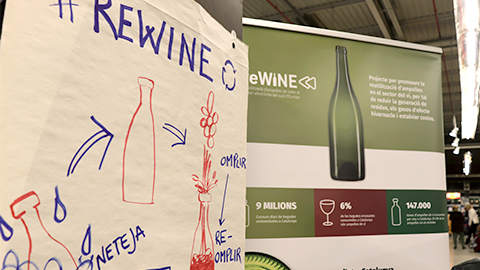

The reWINE project, coordinated by the UAB Research Park and including the involvement of the ICTA-UAB spin-off inèdit, presents the results of its pilot test of a sustainable system of collection, cleaning and reuse of glass bottles of Catalonia's wine industry, developed in the past 20 months.

21/10/2020

The reuse of bottles represents a reduction of 0.56 to 2.6 kg of CO2 per bottle.

The reuse of glass bottles by Catalonia's wine industry could represent an annual saving of over 100 million CO2 and 21,756 tonnes of waste, thereby reducing its carbon footprint by 28%. This reduction would be possible if the 48,346,793 bottles of wine produced and sold in Catalonia were reused. This is one of the conclusions reached by the reWINE project, coordinated by the UAB Research Park and presented today during the seminar on recycling wine bottles entitled “Apostem per reutilitzar les ampolles de vi”. In the event, reWINE’s team explained the main results of the pilot test of a sustainable system for the collection, cleaning, and reuse of glass bottles in the Catalan wine industry developed for 20 months.

The pilot test involved 7 Catalan wineries: la Cooperativa Falset Marçà, Bodegas Torres, Albet i Noya, la Viñeta, Talcomraja, Vins Pravi and Joan Ametller, and more than 30 shops, 50 restaurants, 2 wholesalers, 3 landfills of the Consortium for the Management of Waste from the Vallès Oriental and 2 washing plants.

During the pilot test, 150,000 bottles with the reWINE label were sold and 82,239 recovered. Five different scenarios were explored to achieve this. On the one hand, bottles were collected through the participating restaurants. On the other hand, through businesses with incentive systems. For example, several of the Veritas and Ametller Origen stores paid 10 cents to consumers who returned a bottle labeled reWINE. In the Vallès, four Caprabo establishments also participated in the pilot programme, selling reWINE bottles which consumers had to return to three green points. Some small establishments applied a deposit to the bottle (between 0.13 and 0.5 cents) once the bottle was recovered.

“The reWINE pilot test has shown that the reuse of bottles in the wine sector is technically feasible and more respectful of the environment. But it is an ambitious initiative that needs more support from the sector and the administration", highlights Juan Fran Sangüesa, head of the Innovation Projects Unit of the UAB Research Park and coordinator of the project.

Environmental benefits of reuse

In the different scenarios, reWINE analysed the entire life cycle of the bottle, from its manufacture, labelling in the cellar and distribution on the market, to the collection of empty bottles, their washing and filling again. The Life Cycle Analysis methodology was used to compare the reuse of bottles up to eight times -optimal number of uses stipulated considering aesthetic and hygienic aspects - versus the use of eight new bottles.

Among the environmental indicators, reWINE team evaluated the carbon footprint, expressed in kg of CO2 equivalent. "Environmental studies indicate that reusable bottles are more environmentally friendly than single-use bottles, because we proved that reuse can save between 0,56 and 2,6 kg of CO2 equivalent per bottle, accumulated after 8 cycles", stated Gabriela Benveniste, project manager of inèdit, the eco-innovation study that participates in the project as responsible for the economic and environmental assessment. For instance, by reusing the 82.239 bottles collected during the pilot test up to 8 times, it might save more than 170,000 kg of CO2 equivalent, which are the emissions that a vehicle would produce while traveling 11 times around the world. In addition, with the reuse of these bottles 34 tonnes of waste were avoided.

According to the studies, these environmental benefits could increase even more if the distance between wine cellars and washing plants is reduced and logistics is simplified. "Our washing plant was located more than 400 km from the different wineries and even so, a saving in the carbon footprint has been demonstrated. If washing plants were located near the wineries, at approximately 60 kilometres, one in each DO to cover the entire Catalan territory, we would further reduce the carbon footprint of reuse and increase savings between 40 and 50%", adds Gabriela Benveniste.

Need for more bottle washing plants

One of the most important challenges to implement reuse in this sector is solving the bottle return system. According to Marta Beltran, project manager at Rezero: "The logistics of collecting the bottles must be easy and convenient, both for points of sale and for consumers”.

"In the catering industry there are already returnable beverages, however reuse is not present in shops", highlights Beltran. This is reflected in the figures of the pilot test: reWINE recovered 21% of reusable bottles in stores and supermarkets, where consumers had to return the empty bottle, while in the catering sector the level of return stood at 96%. "reWINE also showed that the deposit, return and collection system is the most effective instrument to guarantee the return of empty bottles to the establishments by consumers, far above other incentives", she says.

At an economic level, currently the cost of reusing a bottle of wine is slightly higher than buying a new bottle. In this case, the distance from the washing plant and the cost of cleaning the bottles again play an essential role. According to the reWINE team, washing facilities are necessary in Catalonia near the wineries in order to optimize the economic and environmental cost of transport. In this sense, it encourages the Denominations of Origin to each have a shared washing plant with the capacity to wash a large volume of bottles.

More information about reWINE

reWINE is a European project promoted in 2016 by the UAB Research Park, the Catalan Waste Agency, Rezero, inèdit, the Falset Marçà Cooperative, Bodegas Torres and the Infinity washing plant, and is supported by the EU's LIFE Programme.

This information is related to the following SDG

Industry, innovation and infrastructure

Climate action